On June 22nd, in the Bamboo Technology Industrial Park of Jingzhou Miao and Dong Autonomous County, Hunan Leadgoal New Materials Co., Ltd. presented a busy scene. The company is going all out to promote key processes such as the heating of the thermal energy center, the commissioning of the intelligent raw material preparation system, and the installation of molds for intelligent equipment support, and is making a full sprint towards trial production.

In the factory area, the heating – up work of the thermal energy center is carried out in an orderly manner. The staff accurately place the kindling materials. After ignition, the thermal energy is continuously transported through pipelines to the entire production system. In the machine room, professional technicians explain the operation key points and safety regulations of the thermal energy center system while guiding the operators to practice. Beside them, the workers are busy wrapping the exposed pipelines with thermal insulation materials to prevent heat loss.

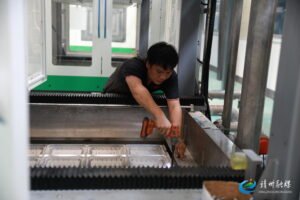

In the main raw material preparation area, technical backbone closely monitor the data on the display screen, repeatedly debug the automatic preparation control system, and continuously optimize the raw material ratio, raw material concentration, equipment parameters, etc. On the production line, workers are using professional equipment to manufacture supporting molds for 30 sets of intelligent production equipment.

Today, we have entered the final debugging stage of trial production. All power equipment is in full operation, and the progress is going smoothly. The team is strictly controlling every link. At present, all processes are operating normally. We are confident that we can trial – produce the first batch of qualified products as planned the day after tomorrow. It is expected that the factory will be fully operational in late July. introduced Gui Cunhong, General Manager of Hunan Lingao New Materials Co., Ltd.

Hunan Leadgoal New Materials Co., Ltd. settled in Jingzhou in 2023, focusing on the green, circular and ecological bamboo resource industry. The project covers an area of 167 mu and is constructed in two phases. The first phase invests 400 million yuan to build a 30,000-ton bamboo fiber technology product production line. The second phase invests 850 million yuan to arrange a 120,000-ton bamboo fiber and 130,000-ton bamboo lignin organic fertilizer production line. It is the bamboo industry project with the largest investment scale and the strongest driving force in Jingzhou.

At present, the first-phase project has completed the renovation of 30,000 square meters of factory buildings, the construction of 3,000 square meters of clean workshops and 2,000 square meters of mold supporting workshops, and the commissioning of 30 sets of equipment. The enterprise has successfully overcome the technical difficulties in the bamboo fiber molding industry. Its bamboo fiber molded lunch boxes, trays and other products have passed a number of international certifications such as the US FDA and European SGS, and have signed orders worth 350 million yuan with well-known enterprises such as Walmart in Canada and Luckin Coffee, which will inject strong impetus into the high-quality development of Jingzhou’s bamboo industry.