40% Space-Saving

Bamboo Pulp Cup Tray

LeadGoal’s 2-cup and 4-cup bamboo pulp carriers are engineered for high-efficiency stacking and nesting, delivering up to 40% space savings compared with conventional molded fiber cup trays.

Bamboo Pulp Cup Tray:

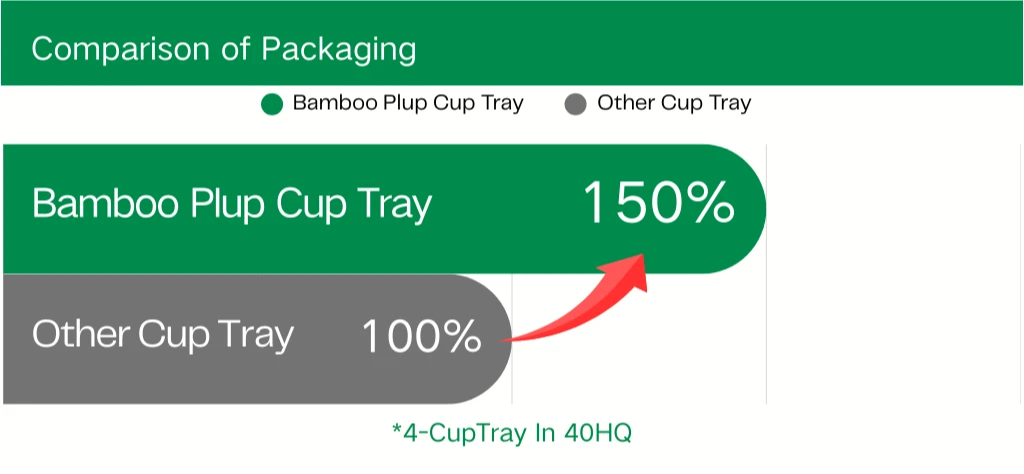

50% More Load

LeadGoal’s bamboo pulp 4 cup carriers deliver unmatched packing efficiency: 996,000 pieces per 40HQ container, compared to only 660,000 pieces for recycled paper pulp or typical molded fiber eco cup trays (both at 600 PCS/CTN). This 50% higher load means significantly reduced per-unit shipping and freight costs, plus optimized storage space – outperforming common competitors like recycled pulp carriers (often less dense due to material and molding differences).

Bamboo Pulp Cup Tray vs Recycled Paper: Odorless, FSC Certified, Stable Supply

LeadGoal self-produced bamboo pulp ensures stable supply, consistent high quality & production capacity, zero unpleasant odor (food-grade & odorless), and full traceability with FSC certification. Recycled pulp alternatives often suffer from inconsistent material quality, unstable supply, emission of foul odors (from bacteria/microbial issues in processing), and no reliable international certification or ongoing supervision. Get superior performance, no off-smells in food contact, and true sustainability for your 2 & 4 cup trays – perfect for beverage shops, delivery, restaurants.

Biodegradable Bamboo Pulp

2 Cup Tray

Eco-friendly 2 cup carrier tray in bamboo pulp – compostable, waterproof, odorless. Ideal for coffee shops, take-away, and restaurants. Secure hold for 2 cups + food. Custom logo/size available. Eco-friendly alternative to plastic.

Biodegradable Bamboo Pulp

4 Cup Tray

Eco-friendly 4 cup carrier tray from bamboo pulp by LeadGoal – fully biodegradable, compostable, waterproof, and odor-free. Perfect for beverage shops, delivery, and events. Holds 4 cups securely + food option. Customize now for your brand.

Why choose us?

- Complete Vertical Integration & Stable Supply Chain:

Own 27 km² bamboo base + raw material factory (180,000 tons/year) + molding base (120,000 tons/year). Full control from raw bamboo to finished products – ensuring consistent quality, reliable delivery, and cost efficiency vs. competitors using unstable external suppliers. - 12+ Years Bamboo Fiber Expertise:

Focused on bamboo fiber since 2013 with mature processes and strict multi-stage quality checks. Delivers higher consistency and reliability than newer brands or general recycled pulp producers. - Self-Produced Bamboo Fiber – Food-Grade & Odorless:

Food-safe, 100% biodegradable/compostable, non-toxic, naturally odorless pulp. Unlike recycled paper pulp trays that often have unpleasant odors and inconsistent quality from bacteria/microbial issues. - FSC Traceable & Certified Sustainability:

Bamboo traceable with FSC certification and ongoing supervision. Many recycled pulp competitors lack international certifications and consistent oversight. - High Capacity & Customization Flexibility:

11,000+ m² factory, 100+ staff, 260+ lines – supports fast scaling and full OEM/ODM (custom shapes, logos, pads, printing). One-stop service outperforms fragmented suppliers for cafes, restaurants, delivery, and supermarkets.